Table of Contents

If your travel trailer’s electric brakes stop working, stopping distances increase dramatically, a serious safety risk. Most problems stem from the brake controller, wiring connections, or brake components themselves.

Electric brake failure isn’t just inconvenient; it’s dangerous. Whether you’re towing a compact 16-foot camper or a larger 30-foot RV weighing several thousand pounds, functioning brakes are essential for safe stops and controlled descents. The good news? Most electric brake issues can be diagnosed and often fixed with basic tools and knowledge.

How Do Travel Trailer Electric Brakes Work?

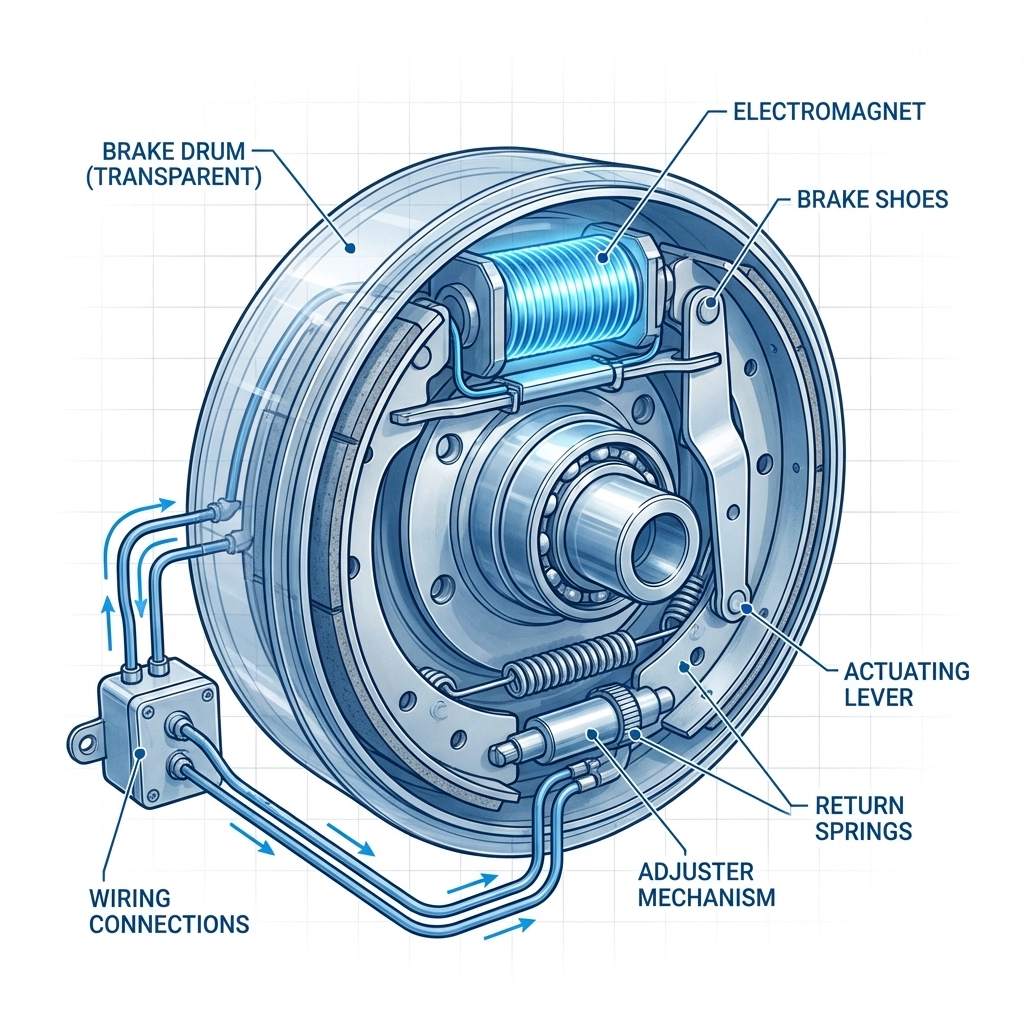

Understanding your trailer’s electric brake system helps you troubleshoot problems more effectively. Unlike hydraulic brakes in your car, travel trailer electric brakes use electromagnets to create stopping power.

The Brake Controller

Your tow vehicle’s brake controller sends a 12-volt signal to the trailer when you press the brake pedal. This device, usually mounted inside your cab, regulates the amount of power sent to the trailer brakes based on your braking intensity.

7-Pin Connector System

The umbilical cord between your truck and trailer carries the brake signal through a 7-pin connector. Pin 5 specifically handles the electric brake circuit, delivering power from the controller to your trailer’s brake assemblies.

Brake Magnets and Drums

Each wheel assembly contains an electromagnet that, when energized, creates friction against the brake drum. This magnetic force activates the brake shoes, pressing them against the drum to slow the wheel. The stronger the electrical signal, the more braking force is applied.

The Complete Circuit

For brakes to work, you need a complete electrical circuit: power flows from the controller through the 7-pin connector to the brake magnets, then returns through the trailer’s frame to ground. Any break in this circuit stops the braking action.

Is It Safe to Tow If Electric Brakes Are Not Working?

The short answer: No, it’s not safe, and in many cases, it’s illegal.

Legal Requirements

Most states require electric brakes on travel trailers exceeding 3,000 pounds gross vehicle weight. Whether you’re pulling a 24-foot camper averaging 6,000 pounds or a compact 18-foot unit around 4,500 pounds, functional brakes are typically mandatory. Check your local regulations, but don’t rely on legal minimums, prioritize safety.

Stopping Distance Impact

Without trailer brakes, your tow vehicle must stop both itself and the trailer using only its own braking system. This dramatically increases stopping distances and puts enormous stress on your truck’s brakes. A 30-foot travel trailer weighing 8,000-10,000 pounds creates massive momentum that your vehicle alone cannot safely control.

Emergency Scenarios

Brake failure becomes especially dangerous on mountain descents, in emergency stops, or during evasive maneuvers. The trailer can push your tow vehicle, causing jackknifing or loss of control. Even a lighter 16-foot camper weighing 3,500 pounds can overwhelm your truck’s braking capacity.

When to Stop Towing Immediately

- Complete brake failure with no braking response

- Trailer pushing the tow vehicle during normal braking

- Any signs of electrical shorting or burning smells

- Steep terrain ahead without functioning trailer brakes

Common Reasons Travel Trailer Electric Brakes Are Not Working

Most electric brake failures trace back to a handful of common issues. Understanding these helps you diagnose problems systematically.

Brake Controller Issues

Improper Setup or Calibration

New installations often suffer from incorrect controller settings. The gain setting might be too low, or the controller may not be properly synchronized with your brake pedal. Many controllers require initial calibration to match your driving style and trailer weight.

Faulty Controller

Controllers can fail internally, losing the ability to send proper voltage signals. If your controller shows no output when tested with a voltmeter, replacement is likely necessary. This is especially common in older units or those exposed to moisture.

7-Pin Connector or Wiring Problems

Corrosion and Oxidation

The 7-pin connector is exposed to road salt, moisture, and debris. Pin 5 (brake circuit) commonly corrodes, creating resistance or complete signal loss. White or green corrosion around pins indicates oxidation that blocks electrical flow.

Loose or Broken Wires

Road vibration and repeated connecting/disconnecting can loosen wire connections or break strands inside the connector. Even partially broken wires can cause intermittent brake failure or reduced braking power.

Blown Fuse or Electrical Power Loss

Tow Vehicle Fuse Panel

Most vehicles have a dedicated fuse for the trailer brake circuit. A blown fuse cuts power completely, making brakes non-functional. Check both the main brake fuse and any auxiliary trailer fuses in your vehicle’s fuse panel.

Shared Circuits

Some vehicles share the brake circuit with other trailer functions. If your trailer lights work but brakes don’t, the problem likely lies downstream from the fuse panel.

Brake Magnet or Drum Wear

Magnet Not Engaging

Worn electromagnets lose their ability to create sufficient magnetic force. You might hear clicking but feel no braking response. Magnets wear down over time, especially with frequent use or exposure to moisture.

Excessive Drum Wear

Brake drums can wear beyond serviceable limits, preventing proper shoe contact. Deep grooves or out-of-round drums reduce braking effectiveness even with functioning magnets.

Grounding Problems

Poor Ground Connection

Electric brake circuits require good ground connections to complete the circuit. Corroded ground straps, loose frame connections, or poor contact with clean metal all prevent proper brake function.

Frame Grounding Issues

The trailer frame serves as the return path for the electrical circuit. Rust, paint, or debris at ground connection points can interrupt this return path, stopping brake operation.

How to Fix Travel Trailer Electric Brakes (Step-by-Step)

Follow these systematic steps to diagnose and repair electric brake problems safely.

Step 1 – Check the Brake Controller Settings

Start inside your tow vehicle. Verify the controller has power (display should be illuminated) and check all settings. Test the manual brake activation button, you should hear clicking from the trailer if brakes are receiving power. Adjust the gain setting to ensure adequate but not excessive braking force.

Step 2 – Inspect the 7-Pin Plug and Wiring

Disconnect the 7-pin connector and inspect both male and female ends. Look for corrosion, bent pins, or burned contacts. Clean any corrosion with electrical contact cleaner and a wire brush. Check that pin 5 (brake circuit) makes solid contact when connected.

Step 3 – Test Electrical Output at the Trailer

Using a voltmeter, test for 12 volts at the brake wire connection inside the trailer connector. Have someone activate the brake controller while you measure voltage. No voltage indicates an upstream problem; proper voltage suggests trailer-side issues.

Step 4 – Inspect Brake Assemblies and Magnets

Remove wheel covers and inspect visible brake components. Look for worn magnets (shiny contact surfaces), damaged wires, or loose connections. Test individual magnets by applying 12 volts directly, functioning magnets should click audibly and engage firmly.

Step 5 – Perform a Safe Test Tow

After repairs, test brakes in a safe area at low speeds. The controller’s manual activation should provide immediate braking response without the trailer pushing or pulling to one side. Gradually test at normal speeds, ensuring consistent brake performance.

Important Safety Note: If you’re uncomfortable with electrical work or brake inspection, consult a qualified RV technician. Brake safety is never worth risking.

Signs Your Trailer Brakes Are Not Working Properly

Recognizing brake problems early can prevent dangerous failures and more expensive repairs.

Trailer Pushing Tow Vehicle

The most obvious sign is feeling the trailer push your vehicle during braking. This creates a sensation of reduced braking effectiveness or the vehicle wanting to continue forward despite brake application.

No Resistance When Braking

Properly functioning electric brakes create noticeable resistance when manually activated via the controller. No resistance suggests complete brake failure or very worn components.

Brake Controller Showing No Output

Most controllers display braking intensity or output voltage. Zero output during brake application indicates controller failure or circuit problems.

Uneven or Delayed Braking

Brakes that engage inconsistently or with a delay can indicate intermittent electrical connections, partially worn magnets, or poor ground connections.

Common Mistakes When Troubleshooting Electric Trailer Brakes

Avoid these frequent errors that can delay repairs or create new problems.

Ignoring Ground Wires

Many DIY repairs focus on power connections while overlooking ground wires. Poor grounds cause as many brake failures as power problems but are often harder to diagnose.

Assuming Controller Is Always the Issue

Controllers are reliable components that rarely fail suddenly. Check connections, fuses, and trailer-side components before replacing an expensive controller.

Skipping Brake Adjustment

Even with perfect electrical function, poorly adjusted brakes won’t work effectively. Many “electrical” problems are actually mechanical adjustment issues.

Towing “Just a Short Distance” Without Brakes

No distance is safe without functioning trailer brakes. Even short trips risk accidents, legal liability, and damage to your tow vehicle’s braking system.

FAQs About Travel Trailer Electric Brakes Not Working

Why are my trailer electric brakes not engaging?

Common causes include blown fuses, corroded 7-pin connections, faulty brake controllers, or worn brake magnets. Start by checking the controller settings and fuse panel, then inspect electrical connections systematically.

Can a bad ground cause trailer brakes to fail?

Yes, ground problems are among the most common causes of electric brake failure. The electrical circuit requires a complete path back to the tow vehicle’s battery through the trailer frame and ground connections.

How do I test trailer brakes without towing?

Use your brake controller’s manual activation button while someone observes the wheels. You should hear clicking sounds from engaged magnets and see slight wheel resistance when trying to turn them by hand.

Do electric trailer brakes need regular adjustment?

Yes, brake shoes wear over time and require periodic adjustment to maintain proper contact with drums. Most manufacturers recommend checking adjustment every 3,000 miles or seasonally.

When dealing with electric brake issues on your travel trailer, remember that safety comes first. Whether you’re pulling a compact off-road unit or a larger family camper, properly functioning brakes are essential for safe travels. If you’re uncomfortable with any troubleshooting steps, professional service is always the safest choice.

For more information about trailer safety and maintenance, visit our blog for additional resources and expert guidance.