Table of Contents

An aerodynamic nose cone on a travel trailer smooths airflow at the front, reducing pressure drag, improving towing stability, and lowering aerodynamic resistance at highway speeds. This streamlined front profile can improve fuel economy by 5-15% while enhancing crosswind stability during long-distance towing.

What Is an Aerodynamic Nose Cone on a Travel Trailer?

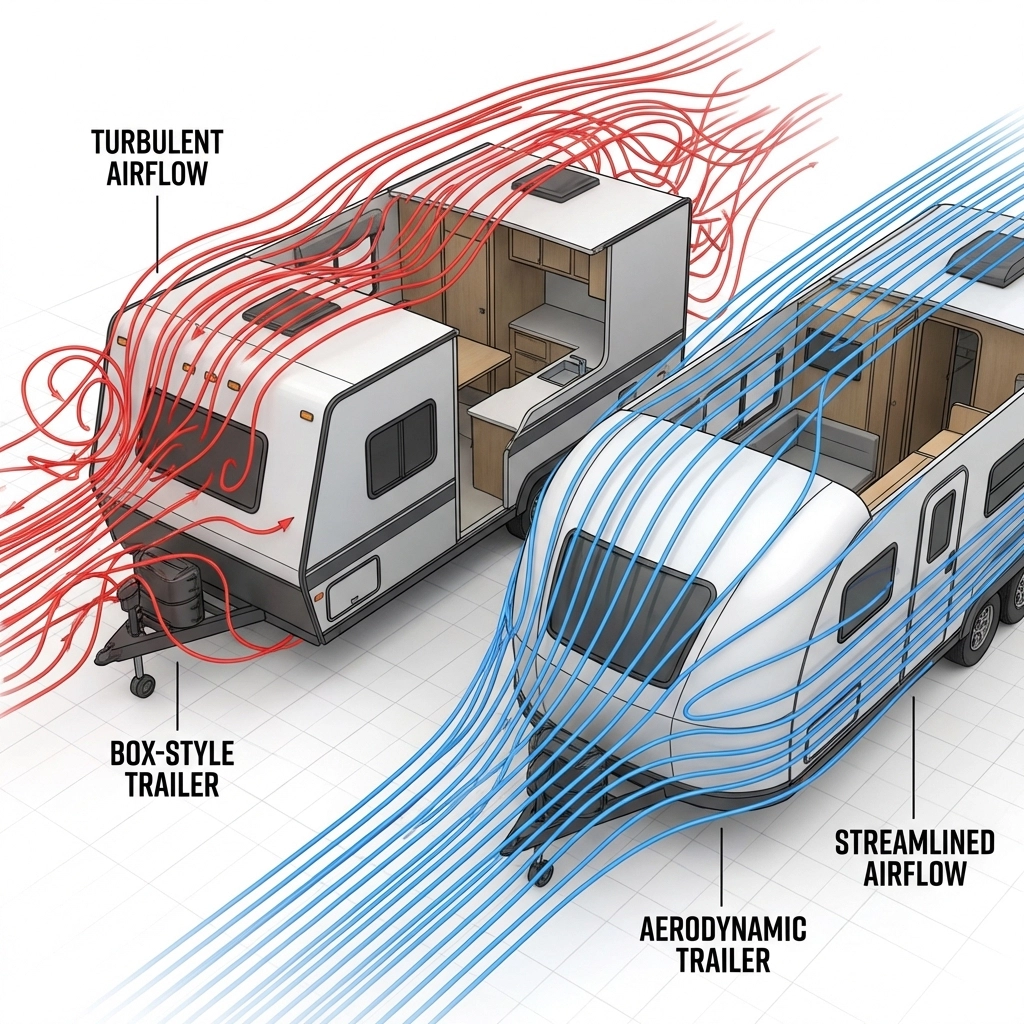

An aerodynamic nose cone is a streamlined front profile designed to smooth airflow over the trailer’s leading edge. Unlike traditional flat-front trailers that create a blunt wall against incoming air, nose cones feature curved or tapered surfaces that gradually redirect airflow around the trailer body.

The nose cone typically extends from the trailer’s front wall in a bulbous or wedge shape, made from lightweight fiberglass or composite materials. This aerodynamic feature appears most commonly on travel trailers ranging from compact 16 ft camper weight models to larger 30 foot RV weight units, where drag reduction becomes increasingly important.

The key difference between nose cone trailers and flat-front designs lies in how they manage the high-pressure zone that forms when air hits the trailer’s leading edge. A well-designed nose cone eliminates the abrupt pressure change that creates significant drag on conventional boxy trailers.

Why the Front of a Travel Trailer Creates So Much Drag

The front of a travel trailer represents the primary source of aerodynamic drag due to several physics principles working against efficient airflow. When a flat-front trailer moves at highway speeds, it creates what’s called stagnation pressure, a high-pressure zone where moving air suddenly stops against the vertical wall.

This stagnation pressure creates several problems:

- Boundary layer formation: Air flowing around the trailer’s edges separates from the surface, creating turbulent wake zones

- Pressure imbalance: High pressure at the front combined with low pressure behind the trailer increases overall drag

- Airflow mismatch: The gap between tow vehicle and trailer disrupts smooth airflow transition

The problem becomes more pronounced with larger trailers. An 18 ft camper weight unit experiences significantly less frontal drag than a 30 ft camper weight trailer simply due to the increased frontal area pushing through the air. This is why aerodynamic improvements become more valuable as trailer size increases.

Understanding boundary layer separation in RVs helps explain why flat surfaces perpendicular to airflow create such substantial drag penalties, especially during sustained highway cruising common in American long-distance towing.

How an Aerodynamic Nose Cone Reduces Trailer Drag

An aerodynamic nose cone works by managing the high-pressure zone at the trailer’s front through gradual pressure transitions rather than abrupt changes. The curved or tapered shape allows air to accelerate smoothly around the trailer body instead of separating immediately upon impact.

Key aerodynamic principles at work include:

- Gradual pressure recovery: Air pressure changes slowly across the nose cone surface, preventing sudden flow separation

- Reduced stagnation area: The streamlined shape minimizes the flat surface area perpendicular to airflow

- Improved airflow attachment: Air stays attached to the trailer surface longer, reducing turbulent separation zones

- Better tow vehicle integration: Nose cones help blend airflow from the tow vehicle to the trailer more smoothly

Real-world testing shows nose cones can reduce aerodynamic drag by 10-25% compared to flat-front designs. For a typical 24 ft camper weight trailer towed at 65 mph, this translates to measurable fuel economy improvements, especially during long interstate drives where aerodynamic drag dominates over rolling resistance.

The effectiveness increases with speed, nose cones provide minimal benefit at city speeds but become increasingly valuable above 45 mph, making them particularly beneficial for highway touring and cross-country travel.

Aerodynamic Nose Cone vs Flat Front Travel Trailer

The performance differences between nose cone and flat-front trailers become apparent across multiple metrics that matter to RV owners:

Aerodynamic Drag

- Nose cone trailers: 15-25% lower drag coefficient

- Flat front trailers: Higher drag due to blunt leading edge

- Real-world impact: 1-3 mpg improvement with nose cone design

Crosswind Stability

- Nose cone trailers: Better side-force management due to streamlined shape

- Flat front trailers: More susceptible to sudden crosswind gusts

- Driver experience: Reduced steering corrections and fatigue

Fuel Consumption While Towing

- Nose cone trailers: 5-15% fuel savings at highway speeds

- Flat front trailers: Higher fuel consumption due to increased drag

- Annual savings: $200-800 depending on usage patterns

Driver Fatigue

- Nose cone trailers: Less wind buffeting and smoother towing experience

- Flat front trailers: More aerodynamic turbulence affecting tow vehicle

Even modest front-end shaping significantly outperforms flat-front designs. The curved surface doesn’t need to be dramatic, subtle nose cone profiles still provide meaningful aerodynamic benefits while maintaining interior space and storage capacity.

Do Nose Cones Improve Stability and Safety?

Aerodynamic nose cones contribute to trailer stability and safety through improved airflow management, particularly in challenging driving conditions common during American highway travel.

Highway Crosswind Resistance

Nose cones help trailers track straighter in crosswind conditions by reducing the side-force coefficient. The streamlined front profile creates less aerodynamic disturbance when hit by side gusts, resulting in fewer sudden steering corrections needed by the driver.

Passing Disturbance Reduction

When large trucks pass RV combinations, the aerodynamic wake creates temporary pressure changes that can destabilize flat-front trailers. Nose cones help minimize these effects by managing airflow more smoothly around the trailer’s leading edge.

Indirect Sway Impact

While nose cones don’t directly prevent trailer sway, they contribute to overall stability by reducing the aerodynamic forces that can trigger sway conditions. This becomes particularly important for longer trailers where the 30 ft RV weight distribution creates higher sway sensitivity.

The stability improvements work in conjunction with proper weight distribution and sway control systems. Understanding the relationship between front-end aerodynamics and rear air vortex behind trailer formation helps explain why comprehensive aerodynamic design matters more than individual modifications.

Limitations of Add-On Nose Cones

Aftermarket nose cones face several limitations that reduce their effectiveness compared to integrated aerodynamic designs built into the trailer from manufacturing.

Installation Placement Problems

- Improper mounting angles reduce aerodynamic efficiency

- Structural attachment points may create new turbulence zones

- Gap sealing around mounting hardware becomes critical

Body Integration Mismatch

- Add-on cones may not align properly with trailer body contours

- Size limitations due to transport and storage requirements

- Weight penalties from reinforced mounting systems

Maintenance and Durability Concerns

- Weather exposure affects fiberglass and mounting hardware

- Road vibration can loosen connections over time

- Repair complexity increases with aftermarket modifications

The fundamental limitation is that local optimization doesn’t equal system optimization. A bolt-on nose cone addresses only front-end drag while potentially creating new airflow problems downstream. Effective aerodynamic design requires considering the entire trailer as an integrated system rather than adding individual components.

Professional aerodynamic development involves computational fluid dynamics modeling, wind tunnel testing, and real-world validation, resources unavailable to most aftermarket accessory manufacturers.

How BlackSeries Designs Aerodynamic Front Profiles

BlackSeries approaches trailer aerodynamics through integrated design philosophy rather than add-on solutions. The engineering process prioritizes real-world stability and long-distance towing comfort over marketing claims about fuel economy improvements.

Integrated Airflow Design

Rather than treating aerodynamics as an afterthought, BlackSeries incorporates airflow management into the fundamental trailer architecture. This means front-end shaping works in coordination with roofline transitions, side surface management, and rear wake control.

Field Testing and Validation

Real-world testing in varied conditions, from desert crosswinds to mountain passes, provides validation beyond theoretical aerodynamic modeling. This testing approach ensures aerodynamic features actually improve the towing experience rather than just looking aerodynamic.

Stability-First Philosophy

While fuel economy improvements matter, BlackSeries prioritizes stability and safety benefits from aerodynamic design. This engineering approach recognizes that confident, comfortable towing leads to better long-distance travel experiences regardless of minor fuel economy variations.

The focus remains on creating trailers that handle predictably in challenging conditions while maintaining the durability required for off-road travel trailer applications where aerodynamic benefits must coexist with rugged construction requirements.

FAQ – Aerodynamic Nose Cone Travel Trailer

Does an aerodynamic nose cone really reduce trailer drag?

Yes, properly designed nose cones can reduce aerodynamic drag by 10-25% compared to flat-front trailers. The effectiveness depends on design quality, speed, and integration with overall trailer aerodynamics.

Is a nose cone worth it on a travel trailer?

For trailers used primarily for highway travel at speeds above 45 mph, nose cones provide measurable benefits in fuel economy and stability. The return on investment improves with annual mileage and fuel costs.

Can a nose cone improve towing stability?

Nose cones contribute to stability by reducing crosswind sensitivity and aerodynamic disturbances from passing traffic. However, they work best when combined with proper weight distribution and sway control systems.

Are nose cones effective on off-road trailers?

Off-road trailers benefit from nose cones during highway transit between destinations. The aerodynamic advantages don’t apply during slow-speed off-road driving but improve the overall travel experience.

How does BlackSeries approach trailer front aerodynamics?

BlackSeries integrates aerodynamic shaping into the trailer design rather than using add-on components. This approach ensures aerodynamic features work with the overall trailer system for improved stability and real-world performance.