Table of Contents

Regular wheel bearing inspection is essential for safe towing and preventing catastrophic failures on the road. This comprehensive guide covers everything you need to know about checking, maintaining, and protecting your BlackSeries trailer’s wheel bearings, ensuring years of reliable off-road adventures.

Why Checking Trailer Wheel Bearings Is Critical (U.S. Driving Conditions)

American towing conditions put exceptional stress on trailer wheel bearings. From high-speed interstate travel reaching 70+ mph to rugged off-road trails through the Southwest’s desert heat, your bearings face extreme challenges daily.

High-Speed Highway Stress: Extended highway driving generates significant heat in wheel bearings. At 65 mph, bearings can reach temperatures over 200°F under normal conditions. When bearings begin to fail, temperatures can spike to dangerous levels exceeding 400°F.

Off-Road and Desert Conditions: BlackSeries trailers excel in challenging terrain, but sand, dirt, and water crossings can contaminate bearing grease and accelerate wear. The fine dust in Arizona, Nevada, and Utah desert regions is particularly damaging to inadequately sealed bearings.

Consequences of Bearing Failure: A failed wheel bearing doesn’t just mean inconvenience, it creates serious safety risks. Complete bearing failure can cause wheel detachment at highway speeds, potentially causing multi-vehicle accidents. Even partial failure leads to excessive hub heat that can damage brake components and create fire hazards.

BlackSeries Advantage: BlackSeries trailers are engineered for demanding conditions, but even the most robust suspension systems depend on properly maintained wheel bearings for safe operation.

What Are Trailer Wheel Bearings? (Definitions & Basics)

Wheel bearings are precision-engineered components that allow your trailer’s wheels to rotate smoothly around the axle spindle while supporting the full weight of your loaded trailer.

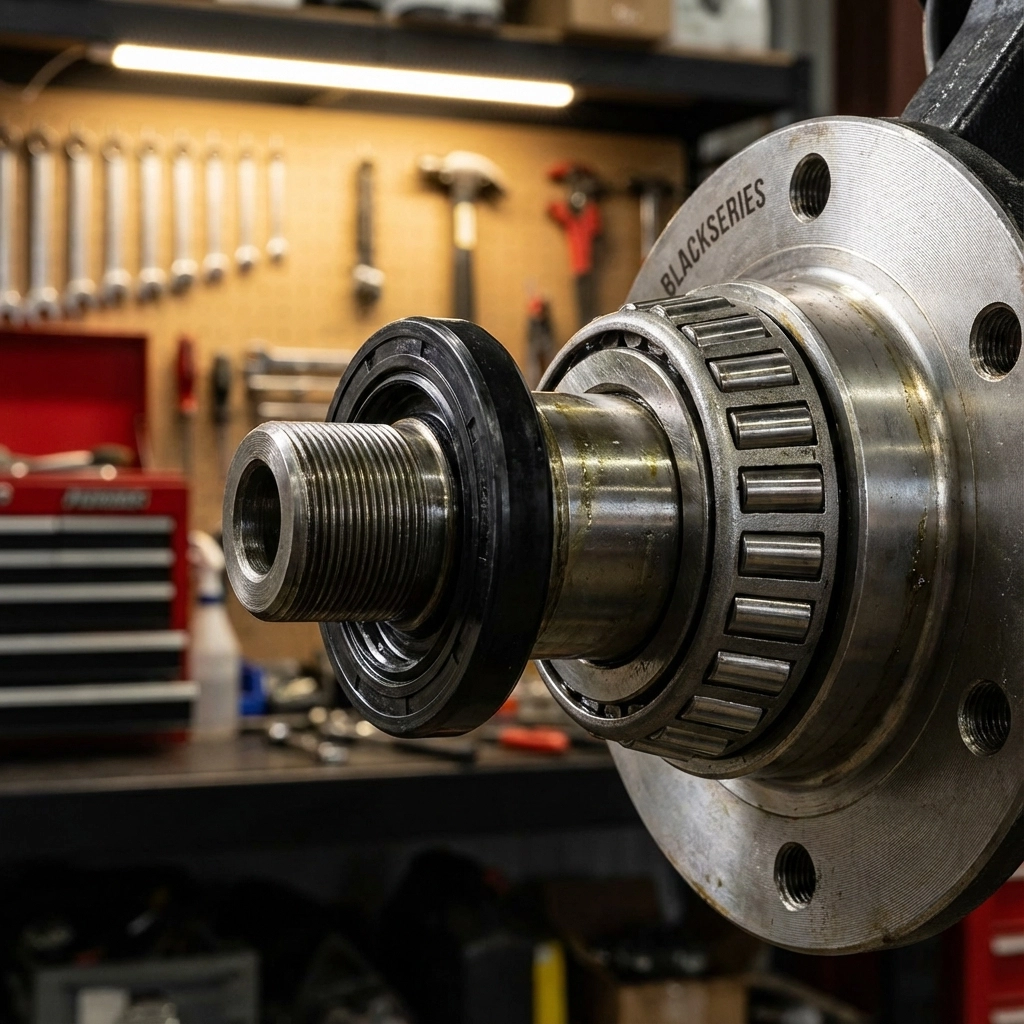

Bearing Components: Most trailer applications use tapered roller bearings consisting of an inner race, outer race, rolling elements (tapers), and a cage that keeps the rollers properly spaced. This design handles both radial loads (trailer weight) and thrust loads (cornering forces).

Dual Bearing System: Each trailer wheel typically uses two bearings, an inner bearing closer to the trailer and an outer bearing near the wheel. The inner bearing is larger and handles most of the load, while the outer bearing provides stability and handles side loads during turning.

Grease Seals: Critical for bearing protection, grease seals prevent lubricant from escaping while keeping contaminants out. A failed seal often leads to rapid bearing failure as grease leaks out and dirt enters the bearing assembly.

BlackSeries Engineering: BlackSeries trailers incorporate heavy-duty bearing assemblies designed for the additional stresses of off-road use, but these superior components still require regular maintenance to perform as designed.

Signs of Bad Trailer Wheel Bearings

Recognizing bearing problems early can prevent roadside emergencies and expensive damage. Watch for these warning signs during your pre-trip inspections and while traveling.

Excessive Heat: The most reliable indicator of bearing trouble is excessive hub temperature. During fuel stops, touch each hub, they should feel roughly the same temperature. If one hub is significantly hotter than others, investigate immediately. Use an infrared thermometer for precise readings; hubs exceeding 250°F warrant immediate attention.

Unusual Noises: Failed or failing bearings often produce distinctive sounds:

- Grinding noises during wheel rotation indicate metal-on-metal contact

- Humming or rumbling that changes with speed suggests worn bearing surfaces

- Clicking or popping during turns may indicate damaged rollers

Wheel Movement: Jack up the trailer and check for play in the wheel assembly. Grasp the tire at the 12 and 6 o’clock positions and attempt to rock it. Any noticeable movement indicates worn bearings requiring immediate attention.

Grease Evidence: Look for grease on the inside of the wheel or around the hub area. Fresh grease leakage often indicates a failing seal, while old, blackened grease suggests overheating or contamination.

Uneven Tire Wear: Worn bearings can cause irregular tire wear patterns, particularly feathering on tire edges or unusual wear on one side of the tire.

How to Check Trailer Wheel Bearings: Step-by-Step

Step 1: Safety Preparation & Tools

Before beginning any wheel bearing inspection, prioritize safety. Never work under a trailer supported only by a jack.

Required Tools:

- Floor jack rated for your trailer’s weight

- Jack stands (place under the frame, never the axle)

- Wheel chocks for the opposite end

- Work gloves and safety glasses

- Infrared thermometer (optional but recommended)

- Basic hand tools for wheel removal

Safety Setup: Position wheel chocks behind the wheels you’re not inspecting. Jack up the trailer at the manufacturer-specified jack points and immediately place jack stands under the frame for support.

Step 2: Check Wheel Play and Rotation

With the wheel off the ground, perform the preliminary bearing assessment:

Movement Test: Grasp the tire at the top and bottom (12 and 6 o’clock positions) and attempt to rock the wheel. Any play indicates bearing wear or improper adjustment. Next, grip the wheel at the sides (3 and 9 o’clock) and repeat the test.

Rotation Assessment: Spin the wheel by hand and listen carefully. Smooth, quiet rotation indicates healthy bearings. Grinding, clicking, or resistance suggests bearing problems requiring further investigation.

Temperature Check: If you’ve been driving recently, use an infrared thermometer to check hub temperature. Record readings for all hubs to identify any outliers.

Step 3: Inspect the Hub and Grease Condition

For a thorough inspection, remove the wheel and examine the hub assembly directly.

Visual Inspection: Look for obvious signs of problems:

- Grease leakage around the hub

- Metal shavings or debris

- Corrosion or rust on visible components

- Cracks in the hub or spindle

Grease Assessment: Remove the dust cap to examine the grease condition. Healthy grease appears red or amber and maintains its consistency. Black, gritty, or separated grease indicates contamination or overheating requiring bearing service.

Seal Inspection: Check the grease seal for damage, cracking, or displacement. A compromised seal allows contaminants to enter while permitting grease to escape.

Step 4: Repack or Schedule Service

Based on your inspection findings, determine the appropriate action:

Continue Using: If bearings show no play, rotate smoothly, and contain clean grease, continue normal operation while maintaining your regular maintenance schedule.

Immediate Service Required: Schedule professional service immediately if you discover:

- Excessive wheel play

- Contaminated or insufficient grease

- Unusual noises or resistance

- Damaged seals or visible bearing components

Trailer Wheel Bearing Maintenance Schedule

Standard Highway Use: For primarily highway towing, inspect bearings every 12 months or 12,000 miles, whichever comes first. This interval works well for travelers who primarily use paved roads and campgrounds.

Off-Road and Overland Use: BlackSeries trailer owners who frequently explore backcountry areas should inspect bearings every 6 months or 6,000 miles. Desert dust, water crossings, and rough terrain accelerate bearing wear and contamination.

After Water Exposure: Always inspect bearings after significant water crossings, boat launching, or camping in wet conditions. Water contamination can rapidly destroy bearing grease and cause failure within hundreds of miles.

Pre-Trip Inspections: Before any major trip exceeding 1,000 miles, perform a complete bearing inspection and service if needed. The cost of preventive maintenance far exceeds the expense and danger of roadside bearing failure.

Best Practices to Extend Trailer Wheel Bearing Life

Quality Grease Selection: Use high-temperature wheel bearing grease rated for at least 450°F. Many professionals recommend red and tacky grease specifically formulated for trailer applications.

Proper Torque Specifications: Follow manufacturer specifications exactly when adjusting bearing preload. Over-tightening creates excessive friction and heat, while under-tightening allows harmful play.

Regular Cleaning: During service, thoroughly clean all bearing components with parts cleaner before repacking. Mixing old and new grease can reduce lubrication effectiveness.

Environmental Protection: Consider bearing buddy caps or similar protective devices to help maintain proper grease levels and exclude contaminants in harsh conditions.

Load Management: Avoid overloading your trailer beyond its rated capacity. Excessive weight accelerates bearing wear and increases operating temperatures.

Common Trailer Wheel Bearing Mistakes

Neglecting Annual Inspections: Many trailer owners only check bearings when problems become obvious. By then, expensive damage has often already occurred to bearings, seals, and potentially the hub assembly.

Mixing Grease Types: Different grease formulations may not be compatible. When in doubt, completely clean out old grease before applying new lubricant.

Improper Adjustment: Bearing adjustment requires specific procedures and torque specifications. Too tight causes overheating; too loose allows damaging play.

Ignoring One Side: Always inspect and service both sides of an axle simultaneously. Bearings typically wear at similar rates, and addressing only one side often leads to problems with the neglected side shortly afterward.

FAQ: Check Trailer Wheel Bearings

How often should I check trailer wheel bearings?

For highway use, inspect bearings annually or every 12,000 miles. Off-road enthusiasts should check every 6 months or 6,000 miles. Always inspect after water exposure or extended desert travel.

Can bad wheel bearings cause a trailer accident?

Yes, failed wheel bearings can cause wheel detachment at highway speeds, creating serious accident risks. Overheated bearings can also damage brake components and potentially cause fires.

Do BlackSeries trailers need special bearing maintenance?

BlackSeries trailers use heavy-duty bearing assemblies designed for off-road use, but they require the same regular maintenance as any quality trailer. Some owners report factory assembly issues, so verify proper bearing service before extended trips.

Can I tow with slightly worn wheel bearings?

Never continue towing with known bearing problems. Even “slight” bearing wear can progress rapidly to complete failure, especially under highway speeds and loaded conditions. Address bearing issues immediately for safety.

Regular wheel bearing maintenance is essential for safe trailer operation and protecting your investment in quality equipment like BlackSeries trailers. When in doubt, consult a qualified trailer service professional for inspection and service. Your safety and the safety of other motorists depends on properly maintained wheel bearings.