Table of Contents

When you’re towing a travel trailer at highway speeds, you’re fighting an invisible enemy: boundary layer separation. This aerodynamic phenomenon significantly impacts your RV’s performance, fuel economy, and stability, especially critical for off-road adventures where every gallon of fuel and ounce of control matters.

Understanding boundary layer separation helps explain why a 30-foot RV struggles more in crosswinds than smaller 16-18 ft campers, and why BlackSeries engineers spend countless hours optimizing airflow around their off-road designs. Let’s dive into what this means for your next adventure.

What Is Boundary Layer Separation in RV Aerodynamics?

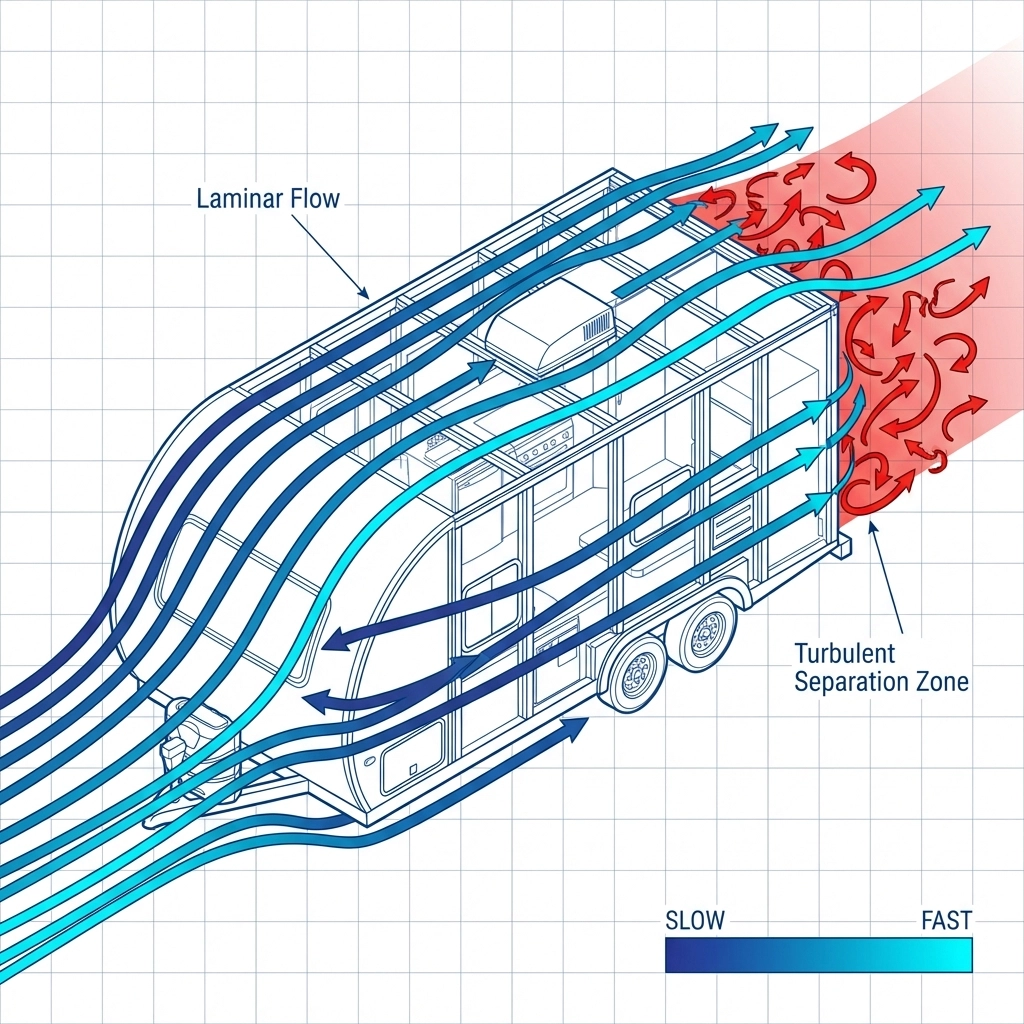

The boundary layer is a thin region of air that flows directly against your RV’s surface as you travel. In this layer, air molecules slow down due to friction with the trailer’s exterior, creating a velocity gradient from zero at the surface to full speed at the layer’s edge.

Boundary layer separation occurs when this smooth airflow detaches from your RV’s surface, typically around the rear corners and back end. When air hits an adverse pressure gradient, where pressure increases downstream, the slow-moving air in the boundary layer can no longer stay attached to the surface.

This separation creates a turbulent wake behind your trailer, dramatically increasing drag and reducing stability. Unlike cars with rounded profiles, RVs have boxy shapes that make separation almost inevitable. The sharp edges on most travel trailers cause airflow to separate abruptly, creating large low-pressure zones that literally pull your trailer backward.

Why RV shapes are problematic: Traditional travel trailers prioritize interior space over aerodynamics, resulting in flat rear ends and sharp corners. A typical 30-foot camper’s blunt shape forces air to make sudden direction changes it simply cannot follow smoothly. This differs dramatically from passenger vehicles, which feature gradual curves designed to keep airflow attached longer.

Understanding laminar vs turbulent flow is crucial here, while turbulent boundary layers resist separation better than laminar ones, the key is managing where and how separation occurs.

The larger your RV, the more dramatic these effects become. A 16 ft camper weight might allow your tow vehicle to power through aerodynamic inefficiencies, but a 30 ft RV weight combined with massive drag penalties can turn mountain passes into fuel-guzzling nightmares.

How Boundary Layer Separation Affects RV Performance

Boundary layer separation doesn’t just hurt fuel economy, it impacts every aspect of your RV’s performance on the road.

Increased Aerodynamic Drag

When airflow separates, it creates a low-pressure wake that effectively makes your trailer “bigger” from an aerodynamic perspective. The drag coefficient of your travel trailer can increase by 30-50% compared to attached flow conditions. This means your tow vehicle works significantly harder to maintain highway speeds.

For perspective: a 24 ft camper with poor aerodynamics might create the same drag as a 30-foot trailer with optimized airflow management. The separation zone behind your trailer acts like a parachute, constantly pulling backward against your tow vehicle’s power.

Crosswind Sensitivity and Stability

Separated airflow makes your RV much more susceptible to crosswinds. When wind hits the side of your trailer, the separated wake area creates uneven pressure distribution, causing dangerous side forces and yawing moments. This is why larger RVs feel “twitchy” in windy conditions, the aerodynamic center of pressure shifts unpredictably.

Fuel Economy Impact

The gas mileage impact when towing a travel trailer stems largely from aerodynamic drag, with boundary layer separation being the primary culprit. Expect 40-60% fuel economy penalties with poorly designed RV aerodynamics, compared to 25-35% with optimized designs.

Towing Dynamics

Separated airflow affects your trailer’s interaction with the tow vehicle. The turbulent wake can create oscillating forces that contribute to trailer sway, making proper electric brake function even more critical for maintaining control.

These effects compound in challenging environments. Mountain driving, desert crosswinds, and highway merging all become more demanding when your RV fights aerodynamic separation at every mile.

Boundary Layer Separation in Off-Road RVs: Why It Matters More

Off-road travel trailers face unique aerodynamic challenges that make boundary layer separation management even more critical.

Ground Clearance Complications

Off-road RVs require higher ground clearance, which disrupts smooth airflow underneath the trailer. This creates additional separation points along the trailer’s bottom edge, increasing overall drag. The gap between your tow vehicle and trailer becomes a source of turbulence that wouldn’t exist with lower, street-oriented designs.

External Equipment Impact

Off-road trailer driving requires external equipment, solar panels, spare tires, water tanks, recovery gear, that all disrupt smooth airflow. Each roof-mounted solar panel or side-mounted spare creates its own separation zone, multiplying drag penalties.

Complex Airflow Environments

Unlike highway driving, off-road adventures often involve variable speeds through complex terrain. Driving dirt roads at 45-55 mph means you’re operating in speed ranges where aerodynamic effects remain significant, but you can’t rely on consistent conditions to optimize your setup.

The BlackSeries Approach

BlackSeries engineers recognize that off-road RVs can’t ignore aerodynamics. While maintaining the rugged capability needed for remote adventures, strategic design elements help manage boundary layer separation. This includes optimized equipment mounting locations, strategic front end shaping, and careful attention to how external gear interacts with airflow.

The key insight: off-road capability and aerodynamic efficiency aren’t mutually exclusive when approached thoughtfully during the design phase.

RV Aerodynamic Drag Reduction Techniques

Reducing boundary layer separation requires strategic design approaches that work within RV packaging constraints.

Optimized Front Profiles

- Rounded nose cones and gentle front edge radii help air attach to the surface initially

- Strategic front-to-side transitions reduce separation at the trailer’s leading edges

- Lower front edges that gradually rise help air flow smoothly over the roof

Roof-Mounted Equipment Management

- Streamlined solar panel mounting that minimizes airflow disruption

- Strategic placement of vents, antennas, and AC units to work with natural airflow patterns

- Integration of equipment into smooth fairings rather than surface-mounted accessories

Underbody Airflow Control

- Partial belly pans that smooth airflow underneath without compromising ground clearance

- Strategic placement of tanks and equipment to minimize turbulence

- Attention to axle and suspension component positioning

Rear Wake Reduction

- Gentle taper angles on the rear corners where packaging allows

- Rear spoilers or deflectors that help manage separation

- Strategic venting that reduces pressure differential across the trailer

The most effective solutions integrate multiple techniques rather than relying on single modifications. This systematic approach explains why frontal area management requires comprehensive design thinking.

How BlackSeries Engineers Address Boundary Layer Separation

BlackSeries takes a holistic approach to aerodynamic optimization that balances off-road capability with airflow efficiency.

Design Philosophy

Rather than treating aerodynamics as an afterthought, BlackSeries incorporates airflow considerations from the initial design phase. This means evaluating how every external component, from spare tire placement to solar panel integration, affects overall aerodynamic performance.

Testing and Validation

BlackSeries utilizes computational fluid dynamics (CFD) modeling combined with real-world testing to understand how boundary layer separation affects their specific designs. This isn’t about achieving sports car aerodynamics, but about optimizing within the constraints of off-road functionality.

Strategic Component Integration

External equipment mounting considers airflow interaction. Solar panels integrate smoothly rather than creating sharp edges. Spare tire placement balances accessibility with aerodynamic impact. Even mundane items like propane tank covers receive attention for their airflow effects.

Why This Matters for Expedition Travel

Long-distance expedition travel amplifies every inefficiency. When you’re covering thousands of miles to remote destinations, the fuel savings and stability improvements from managed boundary layer separation become significant practical advantages. This isn’t just about better fuel economy, it’s about extending your range to reach more remote destinations.

The BlackSeries engineering approach proves that rugged off-road capability and aerodynamic thoughtfulness can coexist when prioritized from the design phase.

Common Myths About RV Aerodynamics

Several misconceptions persist about RV aerodynamics and boundary layer separation.

“Aerodynamics Don’t Matter Below 65 MPH”

False. Aerodynamic drag increases with the square of velocity, so effects are significant even at moderate speeds. Driving at 50 mph still involves substantial drag penalties from boundary layer separation. While the absolute drag force is lower, the percentage impact on fuel economy remains meaningful.

“Only Fuel Economy Is Affected”

Incorrect. Boundary layer separation affects stability, crosswind sensitivity, towing dynamics, and overall driving experience. The turbulent wake behind your trailer influences how it responds to steering inputs, wind gusts, and road irregularities.

“Off-Road RVs Can’t Be Aerodynamic”

This assumes aerodynamics require compromising off-road capability. In reality, thoughtful design can improve aerodynamics while maintaining ground clearance, approach angles, and equipment accessibility. It’s about optimization within constraints, not abandoning functionality.

“Aftermarket Add-Ons Fix Everything”

While some aerodynamic accessories help, they can’t overcome fundamental design issues. Poorly integrated add-ons may actually worsen boundary layer separation by creating new disturbance points. Effective aerodynamic improvements require systematic approaches.

FAQ – Boundary Layer Separation RV

What causes boundary layer separation on RVs?

Boundary layer separation occurs when airflow encounters adverse pressure gradients around your RV’s rear sections and sharp edges. The boxy shape of most travel trailers forces air to make direction changes it cannot follow smoothly, causing the boundary layer to detach from the surface and create turbulent wake zones.

Does boundary layer separation affect RV safety?

Yes, separation significantly impacts stability and crosswind sensitivity. The turbulent wake creates uneven pressure distribution that makes your RV more susceptible to side forces from wind gusts. This affects handling, especially in challenging driving conditions like mountain passes or exposed highway sections.

Can aerodynamic add-ons reduce boundary layer separation?

Some accessories can help, but they must be properly designed and integrated. Simple additions like rear spoilers or side deflectors may provide modest improvements, but poorly designed add-ons can actually worsen airflow by creating new separation points. The most effective solutions integrate aerodynamic considerations into the original design.

Is aerodynamic optimization worth it for off-road RVs?

Absolutely. Off-road adventures often involve long highway transits to reach trailheads, making aerodynamic efficiency valuable for extended range and reduced fuel costs. Modern off-road RV design can incorporate aerodynamic improvements without compromising capability when approached thoughtfully during the design phase.

How does BlackSeries approach RV aerodynamics differently?

BlackSeries integrates aerodynamic considerations from the initial design phase rather than treating them as afterthoughts. This includes strategic equipment placement, smooth component integration, and using CFD analysis to optimize airflow while maintaining off-road functionality. The focus is on systematic optimization within the constraints of rugged capability requirements.

Understanding boundary layer separation helps explain why some RVs perform better than others on the highway. While perfect aerodynamics isn’t realistic for off-road travel trailers, thoughtful design approaches can significantly reduce drag penalties and improve overall performance. Whether you’re considering a 16 ft camper or a full 30-foot adventure rig, aerodynamic efficiency should factor into your decision-making process alongside traditional concerns like interior space and off-road capability.