Table of Contents

A weight distribution hitch (WDH) is essential when towing heavy trailers over 5,000 pounds GVWR, redistributing tongue weight across your vehicle’s axles for safer handling. While installation may seem complex, following proper procedures ensures optimal towing performance. BlackSeries off-road trailers, built for heavy-duty adventures, particularly benefit from properly configured weight distribution systems for enhanced stability on challenging terrain.

What Is a Weight Distribution Hitch?

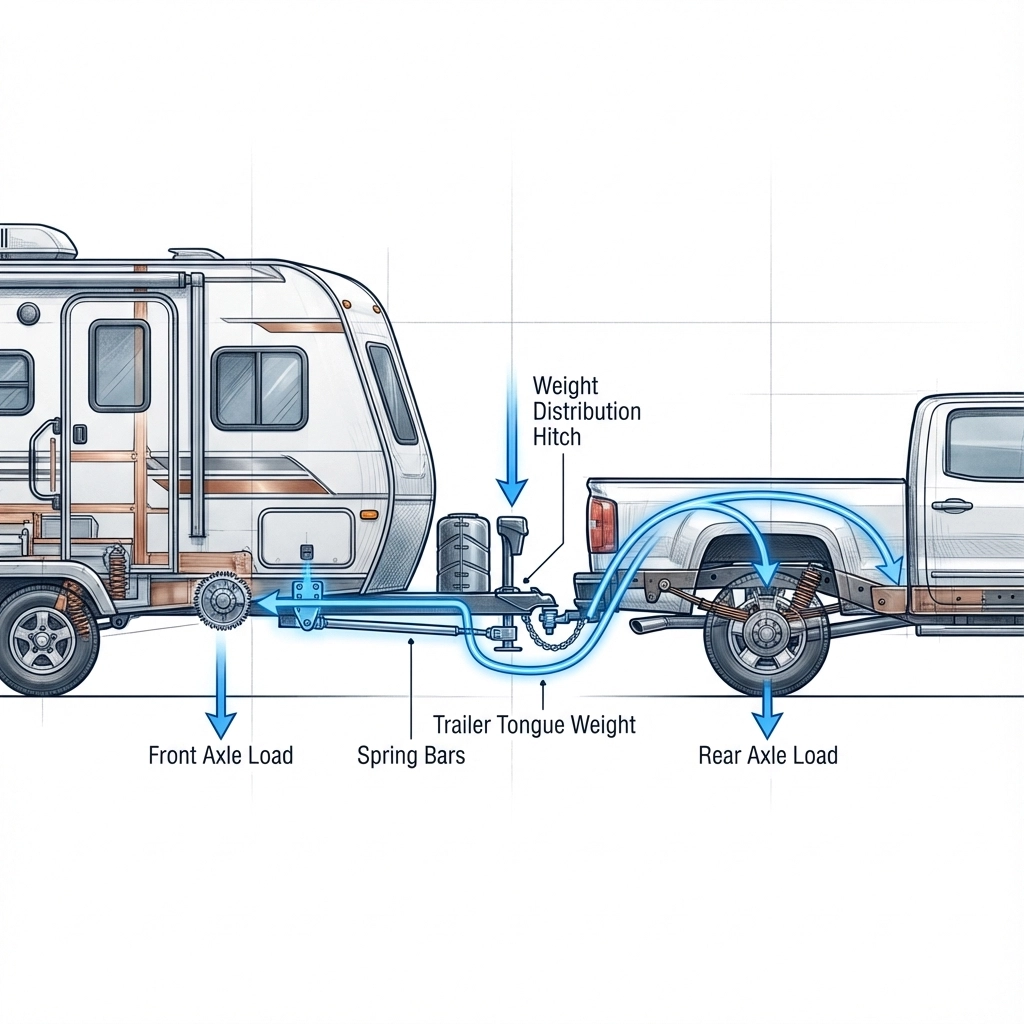

A weight distribution hitch is a specialized towing system that redistributes the tongue weight of your trailer across both the tow vehicle’s front and rear axles, as well as the trailer’s axles. Unlike a standard ball mount that concentrates all tongue weight on the rear of your tow vehicle, a WDH uses spring bars and chains to transfer some of that weight forward and backward.

This redistribution solves three critical towing problems: rear vehicle sag, reduced steering control, and dangerous trailer sway. When your tow vehicle’s rear end drops significantly under tongue weight, it lifts the front wheels, reducing traction and steering responsiveness. The weight distribution system counteracts this by applying leverage through spring bars, restoring proper weight balance.

According to U.S. Department of Transportation guidelines, weight distribution hitches are recommended for trailers with a gross vehicle weight rating (GVWR) over 5,000 pounds or when tongue weight exceeds 10% of the tow vehicle’s gross vehicle weight rating. Many states require WDH systems for commercial towing operations, and some RV manufacturers void warranties if proper weight distribution isn’t maintained.

The key difference between a weight distribution hitch and a regular ball mount lies in the spring bar mechanism. Standard hitches simply connect the trailer to a ball mounted on the receiver, while WDH systems include adjustable spring bars that create leverage points on both the vehicle and trailer frames.

For comprehensive towing fundamentals, check our detailed RV towing guide that covers vehicle preparation and safety protocols.

Do You Need a Weight Distribution Hitch?

Determining whether you need a weight distribution hitch depends on several measurable factors, starting with your trailer’s gross vehicle weight rating and tongue weight specifications. If your trailer’s GVWR exceeds 5,000 pounds, or if the tongue weight is more than 600 pounds, a WDH becomes essential for safe operation.

The most practical test involves measuring your tow vehicle’s stance before and after hitching. When properly loaded, your vehicle should maintain level ride height, if the rear drops more than 2 inches or the headlights point skyward, you need weight distribution. This sagging indicates that tongue weight is overwhelming your rear suspension, compromising steering control and braking effectiveness.

BlackSeries off-road trailers typically fall into weight categories requiring WDH systems. The HQ17 model, for instance, has a GVWR of approximately 4,850 pounds loaded, placing it near the threshold where weight distribution becomes beneficial. The larger HQ19 and HQ21 models, with GVWRs exceeding 6,000 pounds, absolutely require proper weight distribution for safe towing.

SUV and pickup truck combinations present different challenges. Full-size pickups with robust suspensions may handle moderate tongue weights without visible sagging, but this doesn’t eliminate the need for weight distribution. Even if your vehicle appears level, improper weight distribution affects braking distances, studies show that unbalanced loads can increase stopping distances by up to 40% in emergency situations.

Off-road trailer scenarios add complexity because uneven terrain amplifies weight transfer effects. When climbing steep grades or navigating rocky trails, improper weight distribution can cause dangerous trailer sway or reduce traction at critical moments. Our guide on preventing trailer sway while towing provides additional stability insights for challenging conditions.

To calculate exact tongue weight requirements, use our tongue weight calculation guide for precise measurements that determine your WDH needs.

Tools & Parts You Need Before Installation

Before beginning installation, gather the essential tools and components to ensure a smooth setup process. Most weight distribution hitch installations require basic hand tools, but precision and torque specifications are critical for safety.

Required Tools:

- Torque wrench (capable of 250+ ft-lbs)

- Socket set with metric and standard sizes

- Measuring tape (minimum 25 feet)

- Level (both 2-foot and torpedo levels)

- Safety glasses and work gloves

- Jack stands or blocks for vehicle support

Essential WDH Components:

- Hitch head assembly with integrated ball

- Spring bars (matched to your tongue weight)

- Lift chains or L-brackets

- Snap-up brackets for trailer frame mounting

- Adjustment hardware and washers

- Hitch pin with clip

Safety Equipment:

- Wheel chocks for both vehicle and trailer

- Safety chains (separate from WDH chains)

- Breakaway cable

- Electrical connector (7-pin recommended)

The quality of your components directly affects towing safety. Heavy-duty off-road applications require higher-grade steel construction and reinforced attachment points. Many standard WDH systems use 800-1,200 pound weight ratings, but aggressive off-road use may require 1,400+ pound capacity spring bars for durability.

Professional installation typically costs $200-400, but DIY installation saves money while providing valuable understanding of your towing system. The process requires 2-3 hours for first-time installers, with subsequent setups taking 30-45 minutes once familiar with the procedure.

How to Hook Up a Weight Distribution Hitch (Step-by-Step)

Step 1 – Measure Your Unloaded Vehicle Height

Begin with your tow vehicle unloaded and parked on level ground. Measure from the ground to the bottom of the wheel wells on all four corners, recording these baseline measurements. Also measure the height of your trailer coupler to determine the proper hitch head angle.

These initial measurements are critical reference points for verifying proper weight distribution after installation. Mark the measurement points with chalk or tape to ensure consistent readings throughout the setup process.

Step 2 – Set the Hitch Head Angle

Insert the hitch shank into your receiver tube, choosing either the “rise” or “drop” position based on your vehicle-trailer height difference. The goal is positioning the hitch head so the trailer ball sits 1-3 inches higher than the trailer coupler when unhitched.

Install the adjustment rod with the appropriate number of spacer washers. More washers angle the head downward for less leverage, while fewer washers increase the upward angle. Consult your specific WDH manual for the exact washer count based on your tongue weight requirements.

Secure the head assembly with the conical-tooth washer and hex bolt, torquing to manufacturer specifications (typically 250-350 ft-lbs). This connection bears significant stress and must be properly tightened.

Step 3 – Mount the Spring Bars

Apply grease to all spring bar attachment points before installation. Most modern WDH systems use either round bars that insert from underneath and rotate into position, or trunnion-style bars that angle onto the head and pivot upward.

Ensure the spring bars are properly seated in the head assembly channels. Improper seating causes premature wear and potential failure during towing. The bars should move smoothly through their range of motion without binding or interference.

Step 4 – Attach Chains or L-Brackets

Position the snap-up brackets on your trailer frame, using the spring bar geometry as a guide for optimal placement. The brackets must mount to structurally sound frame sections, avoid mounting to thin sheet metal or non-load-bearing components.

Install the lift chains or L-brackets with a minimum of five chain links between the hook and spring bar. This spacing allows proper leverage development while preventing over-tensioning. Each manufacturer specifies exact chain positioning for optimal weight transfer.

Step 5 – Apply Tension Evenly

Connect your trailer to the hitch ball and engage the coupler latch securely. Lower the trailer jack to transfer weight to the hitch, then begin applying spring bar tension gradually. Work alternately between left and right sides to maintain even pressure.

The spring bars should be tensioned until your tow vehicle returns to approximately 50-75% of its original ride height. Complete leveling isn’t always necessary, the goal is restoring proper front axle weight for steering and braking control.

Step 6 – Recheck Ride Height & Level

Measure your vehicle at the same points recorded in Step 1. The rear should be within 1-2 inches of the original height, while the front should return to near-baseline measurements. If measurements are significantly off, adjust spring bar tension or head angle accordingly.

Take a short test drive to verify handling and stability. The vehicle should track straight with normal steering effort and show no signs of trailer sway or unusual behavior. For detailed towing setup verification, reference our comprehensive travel trailer setup guide.

Proper Weight Distribution Hitch Adjustment Tips

Fine-tuning your weight distribution hitch requires understanding the relationship between spring bar tension, vehicle stance, and load transfer characteristics. Over-tensioning creates harsh ride quality and potential component stress, while under-tensioning fails to achieve proper weight distribution benefits.

The front axle weight test provides the most accurate adjustment verification. With the trailer connected and WDH tensioned, your front axle should carry within 100 pounds of its unloaded weight. Most truck stops and moving companies have certified scales for this verification, though portable wheel scales offer convenience for frequent adjustments.

Monitor tire contact patches as another adjustment indicator. Properly distributed weight creates even tire contact across the tread width on all vehicle tires. Cupped wear patterns on front tires often indicate insufficient weight distribution, while irregular rear tire wear suggests over-tensioning.

Common adjustment errors include asymmetric spring bar tension and neglecting seasonal weight changes. Left-right imbalance causes handling problems and uneven tire wear, while seasonal gear variations (winter vs. summer camping equipment) affect optimal settings. Document your successful configurations for different loading scenarios.

Advanced off-road applications may require custom adjustment approaches. Remote terrain places additional demands on the towing system, making conservative settings more appropriate than maximum performance configurations. Our article on preventing trailer sway while towing covers stability techniques for challenging conditions.

Common Mistakes to Avoid

Weight distribution hitch installation involves several critical failure points that can compromise safety and performance. Understanding these common mistakes helps ensure proper setup and long-term reliability.

Torque Specification Neglect: The most dangerous error involves insufficient torque on critical fasteners. Hitch head bolts, spring bar pins, and frame mounting hardware must meet manufacturer specifications. Under-torqued connections can fail catastrophically, while over-torquing may strip threads or stress components beyond design limits.

Asymmetric Tension: Left-right spring bar imbalance creates handling problems and accelerated component wear. Always tension spring bars evenly and verify equal chain positioning on both sides. Even small differences can cause the trailer to track poorly or create steering bias.

Incorrect Mounting Points: Frame mounting bracket placement significantly affects weight distribution effectiveness. Mounting brackets to sheet metal, bumper assemblies, or non-structural components creates failure points and reduces load transfer capacity. Always identify true frame rails for bracket attachment.

Ignoring Seasonal Variations: Many towing enthusiasts set up their WDH once and never readjust for different loading conditions. Winter camping gear, water tank levels, and passenger loads all affect tongue weight and require adjustment compensation. Document successful configurations for different scenarios.

Off-road trailer applications compound these challenges because standard setup parameters may not account for aggressive terrain use. BlackSeries trailers are engineered for demanding conditions, but improper WDH setup can overwhelm even the most robust designs. Our off-road travel trailers guide covers specialized considerations for extreme-use applications.

Professional Verification: Consider professional inspection for your initial setup, especially with heavy off-road trailers. Many RV dealers and truck accessory shops offer verification services that can identify setup issues before they become safety hazards.

Best Weight Distribution Hitch for Heavy & Off-Road Trailers

Selecting the appropriate weight distribution hitch for heavy-duty and off-road applications requires understanding the additional stresses imposed by aggressive terrain and higher trailer weights. Standard WDH systems designed for highway travel may not provide adequate durability for sustained off-road use.

Heavy-duty applications typically require spring bars rated for 1,200-1,600 pounds of tongue weight, significantly higher than standard 800-1,000 pound systems. The increased capacity provides safety margins for dynamic loading conditions encountered on uneven terrain, where static tongue weights can multiply during articulation.

Key Features for Off-Road WDH Systems:

- Heat-treated spring bars with corrosion-resistant coatings

- Reinforced head assemblies with oversized pivot points

- Stainless steel or zinc-plated hardware for corrosion resistance

- Adjustable friction dampening for sway control integration

- Quick-disconnect capability for off-road unhitching

BlackSeries trailers benefit from premium WDH systems due to their robust construction and off-road capability. The HQ19 and HQ21 models, with loaded weights approaching 7,000+ pounds, demand professional-grade weight distribution for optimal performance. These trailers’ independent suspension systems work most effectively when proper weight distribution maintains ideal axle loading.

Friction sway control integration becomes critical for off-road applications. While electronic sway control systems offer convenience, mechanical friction units provide consistent performance regardless of electrical system status. Combined WDH/sway control units streamline installation while ensuring integrated performance.

Consider upgrading to commercial-grade systems for frequent off-road use. These units typically feature serviceable components, higher load ratings, and more robust construction than consumer-oriented systems. The additional investment pays dividends in reliability and reduced maintenance requirements.

For specific trailer recommendations, explore our guides on best off-road camper trailers and off-road trailer considerations that detail weight distribution requirements for different adventure scenarios.

FAQ

Do I really need a weight distribution hitch?

Yes, if your trailer’s GVWR exceeds 5,000 pounds or tongue weight is over 600 pounds. Even if your vehicle appears to handle the load, proper weight distribution improves braking, steering control, and overall safety. Many insurance policies and manufacturer warranties require WDH use for heavy trailers.

Can I install a weight distribution hitch myself?

Most experienced DIY mechanics can install a weight distribution hitch using basic tools and following manufacturer instructions. However, proper setup requires understanding of weight transfer principles and precise adjustments. Professional installation is recommended for first-time users or complex applications.

How tight should a weight distribution hitch be?

Spring bars should be tensioned until your tow vehicle returns to 50-75% of its original unloaded ride height. Over-tensioning creates harsh ride quality and component stress, while under-tensioning fails to achieve proper weight distribution benefits. Always follow manufacturer specifications for your specific setup.

Is a weight distribution hitch required by law in the US?

Federal law doesn’t specifically mandate WDH use for recreational towing, but many states require proper weight distribution for trailers over certain weights. Additionally, most RV manufacturers and insurance companies require WDH use for trailers exceeding specific weight thresholds to maintain warranty coverage.

Can I use a WDH for off-road trailers?

Yes, but off-road applications require heavy-duty systems designed for additional stresses. Standard highway-rated WDH systems may not provide adequate durability for sustained off-road use. Consider commercial-grade units with higher load ratings and corrosion-resistant construction for aggressive terrain applications.

For comprehensive towing preparation and safety protocols, reference our detailed RV towing guide before your next adventure.

Final Safety Checklist Before You Tow

Before departing on any towing adventure, complete a comprehensive safety verification to ensure all systems are properly configured and secure. This final checklist prevents common oversights that can lead to equipment failure or safety hazards.

Hitch Connection Verification:

- Coupler properly latched and locked

- Safety chains crisscrossed and properly secured

- Breakaway cable connected to tow vehicle frame

- All hitch pins secured with clips

Weight Distribution System:

- Spring bars properly tensioned and secured

- Lift chains or brackets engaged in raised position

- All mounting hardware torqued to specification

- No interference between moving components

Electrical and Brake Systems:

- Trailer lights functioning (turn signals, brake lights, running lights)

- Brake controller programmed for trailer weight

- Breakaway battery charged and connected

Final Test Drive Protocol:

Begin with a low-speed parking lot test to verify basic handling and brake function. Gradually increase speed while monitoring for unusual behavior, excessive sway, or steering difficulties. A properly configured weight distribution hitch should provide confident, stable towing characteristics.

For complete pre-departure preparation, including detailed trailer setup procedures, consult our travel trailer setup guide that covers all systems verification before hitting the road.

Proper weight distribution hitch installation and adjustment ensures safe, confident towing for your off-road adventures. Take time to understand your specific system’s requirements and never compromise on safety for convenience. BlackSeries trailers are engineered for demanding conditions, but they perform best when supported by properly configured towing systems that match their capabilities.